#1 Mistake Engineers Make that Increases Stormdrain Costs

We get a lot of calls from design engineers with the same question:

“I am designing a project that will have 18”, 24”, and 36” stormdrain pipe. What pipe material option is the least expensive for these sizes?”

Our answer: none of them

The Surest Way to Lower Costs is to Allow Competition

The problem with this question is that it assumes that you have to specify a single product for each pipe line in your project. Instead of specifying a product, you should be designing a system that meets the project needs.

The specific material used in any system is only important in that it meets the design criteria of the project. You want the pipe to function hydraulically, perform structurally, and provide long term service life to the owner.

Aluminized corrugated steel pipe, HDPE dual wall pipe, and reinforced concrete pipe all meet these criteria.

Download a Sample Stormdrain Pipe Specification with Material Options

Hydraulic Performance

The spiral rib corrugation profile of steel pipe has the same Manning’s coefficient as HDPE and RCP (0.012). These products can be used interchangeable without impacting your hydraulics.

Structural Capability

All three products can support H-20 highway loads and are allowed per GDOT for cross drain applications.

Long Term Durability

All three products provide a 75-100 year minimum service life.

How Much Does it Cost to Specify a Single Product?

Basic economics tells us that competition lowers prices.

The effect of competition specifically on storm drain pipe costs has been well documented through independent research by the FHWA and various state DOTs as well as through industry research studies.

- The National Cooperative Highway Research Program (NCHRP) published a report in 2015 titled “Proposed Practice for Alternative Bidding of Highway Drainage Systems.” The report states that “The inclusion of multiple equivalent options during the bid phase of projects has been shown to reduce costs through increased competition.” Read the excerpt here

- South Dakota DOT published a report in 1998 titled “Evaluation of High Density Polyethylene (HDPE) Pipe.” The report states that “when polyethylene pipe is included in the construction plans as an alternate to reinforced concrete pipe or corrugated metal pipe, bid prices for each type of pipe are generally lower” and “…when projects are bid as reinforced concrete only, installed costs are an average of 29.2 percent higher on 305 mm to 915 mm (12 to 36 in) drain pipe than when polyethylene is allowed as an alternative.” Read the excerpt here

- BCC Research published a report in 2016 titled “Comparison of Stormwater Pipe Installation Lengths and Costs in Texas” that compared the installed storm drain pipe system costs for cities in Texas that a allow a single product choice for storm drainage vs cities in Texas that allowed more than one product choice for storm drain pipe. The report states that “key project findings indicate that communities with open competition enjoy lower pipe cost, on average, for stormwater projects, reaching savings of up to 57% in comparison to municipalities employing closed competition practices.” Read the report here

The Cost of Specifying a Single Product Choice for a Project in the Atlanta Area

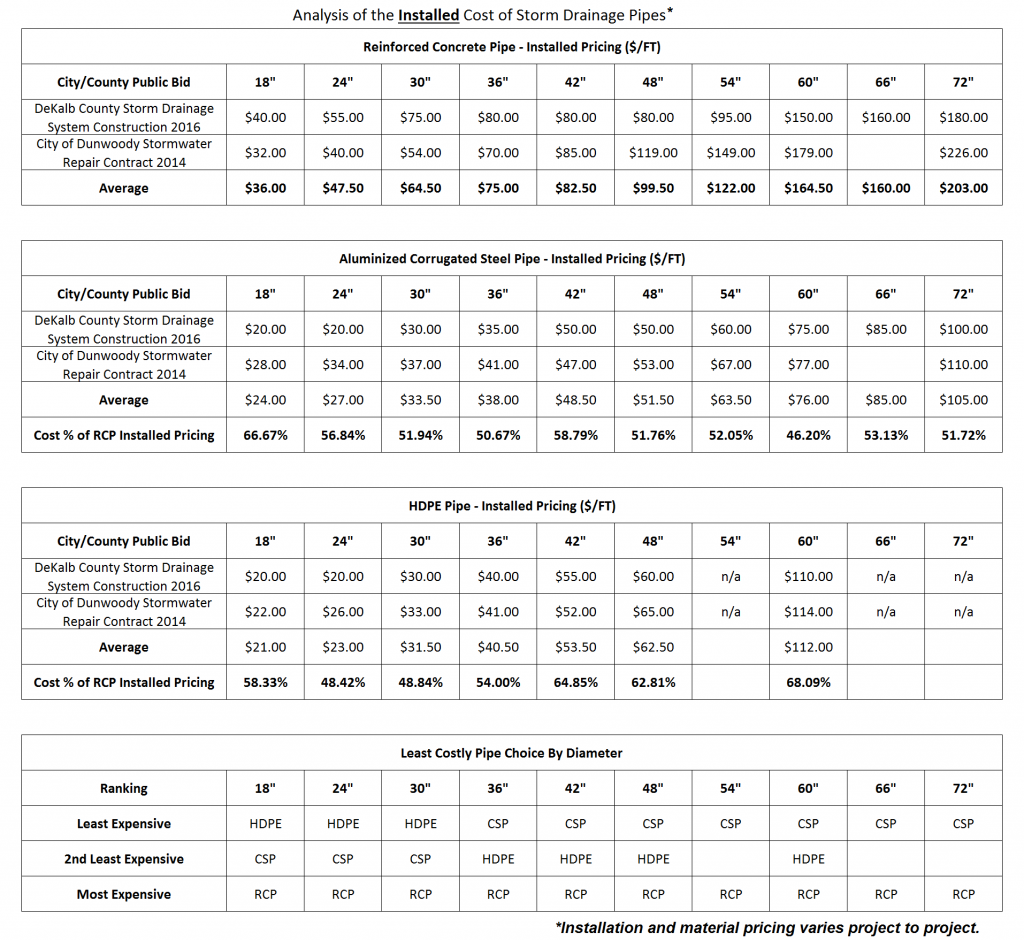

We pulled publically available stormdrain construction contracts to compare the installed cost of various stormdrain materials in the Atlanta area.

Depending on the diameter, the installed cost of reinforced concrete pipe is 50% to 100% higher than the installed cost of corrugated steel pipe or corrugated HDPE pipe in these contracts.

You can see that the least costly pipe material choice varies based on the diameter of the pipe. This choice is also affected by municipal regulations and fluctuations in material prices over time.

How to Reduce Stormdrain Costs

The easiest way for you to ensure that your client gets the best storm drain system pricing is to allow multiple pipe material options. With this one simple step you:

- Increase the number of manufacturers competing for the project, which lowers bid prices.

- Protect your project from fluctuations in the material pricing for these products.

- Reduce your work on the back-end of the project because you do not have to review alternate pipe material proposals.

We have put together a sample storm drain pipe material specification you can insert on your drainage plan or pipe profile to allow contractors multiple pipe materials options. The specification includes the industry recommendations for pipe installation and the material requirements to meet GDOT standards.

Download a Sample Stormdrain Pipe Specification with Material Options

If you have more questions about this topic, please feel free to contact our engineering department.